In the world of industrial hardware, innovation often begins not with a grand announcement, but with a quiet observation. That was the case for Green Pin®, whose entry into the aquaculture sector started with a simple question: Could our existing products meet the demanding conditions of fish farming?

The answer, as it turned out, was yes—but not without a journey of adaptation, testing, and collaboration.

Recognising a niche

The aquaculture industry, particularly in regions like Norway, places high demands on the components used to anchor and secure fish cages. These structures must withstand harsh underwater conditions, dynamic loads, and strict safety regulations. Green Pin® engineers noticed that many of their standard products already aligned with these needs. This sparked a deeper investigation into the sector’s requirements and ultimately led to the decision to develop a dedicated product line. But the goal wasn’t just to enter a new market—it was to do so responsibly, with products that met the highest standards of safety, durability and certification.

Engineering for the Environment

It all began, of course, with research. To gain a deeper understanding of the aquaculture sector’s needs, the Green Pin® team actively connected with customers and distributors through meetings and during their presence at the Aqua Nor and Aqua Sur exhibitions, focusing specifically on the challenges of securing fish cages.

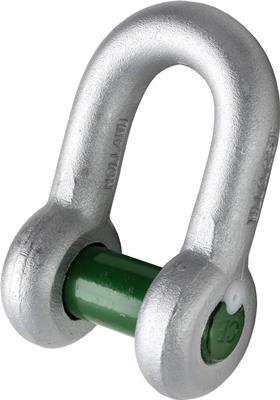

From there, the development of the aquaculture line became a cross-functional effort. Engineers conducted Finite Element Method (FEM) analyses to assess mechanical stresses, while production teams created prototypes for real-world testing. The validation process was thorough, involving fatigue tests, break tests, deformation tests and Magnetic Particle Inspection (MPI) to ensure structural integrity and reliability.

While the development of most components progressed smoothly, the team did encounter a few minor obstacles along the way. One of the more complex technical challenges centered around a specific product, the mooring bolt. Its threaded grooves, designed to allow anchoring grout between the pitches, giving the product extra fixation strength, were unexpectedly filled with zinc. So galvanizing this part proved to be difficult, due to its geometry and the need for consistent corrosion protection. With the support of our partners, the team developed a reliable galvanization method—an essential step for ensuring long-term performance in underwater conditions.

Certification and Compliance

To meet industry standards, our products were certified under DNV and NS 9415. Midway through the project, the standard shifted from NS 9415:2009 to NS 9415:2021 (NYTEK23). Thanks to strong teamwork and collaboration we were among the first to complete the transition—securing our DNV certification while others were still adapting.

The certification process wasn’t just a formality—it was a core part of the product’s development, ensuring that every component could be trusted in demanding marine environments.

Production with Confidence

Unlike many new product lines, production of the aquaculture components began alongside prototyping. Peter Penning, QA & QC Manager and Product Manager mentioned the following: “We were confident from the start. Our products had the right foundation for aquaculture applications, and we believed we could make this a success without needing to reinvent the entire wheel.”

And the Green Pin® team was right, as the existing manufacturing process required only minimal adjustments, such as the addition of a drilling step for the sunken hole plug in the Green Pin® Dee Shackle and the setup of a dedicated welding process for the Mooring T-Bolt.

To ensure quality, each production cell operated under strict specifications, with oversight from team leaders and the quality department. The emphasis was clear: quality, consistency, reliability, and traceability.

Looking Ahead

When asked about the future of the aquaculture product line, Paul Olislagers (Senior Area Sales manager) said the following: ‘’The aquaculture sector is evolving. Fish cages are becoming larger and heavier, and the demand for certified, high-performance hardware is growing. And of course Green Pin® is prepared to scale its offerings accordingly, with future development focused on larger sizes and continued compliance with emerging standards.’’

So what began as an internal observation has now become a fully realized product line. The best solutions are built on understanding, collaboration, and precision. That’s why Green Pin® is the centrepiece of rigging—offering aquaculture products that are below surface, but above standard.

Curious to see what we have to offer?

Go to our website: Fishing & Aquaculture - Green Pin

View our Brochure: GREEN PIN® - AQUACULTURE RANGE

Or visit us at Aqua Nor stand #E-423

GREEN PIN® - AQUACULTURE RANGE

We create high-end lashing and lifting equipment since 1922. A wide range of 100% failsafe products and with a stock availability of 99%. Providing security and safety has always been our highest priority. Let Green Pin® to be the centrepiece of your mooring system.