Macduff Shipyards Limited have recently signed over their latest new build fishing vessel, ‘EXCEL, BF 110’, to owner/skipper Derek Watt, along with son Philip.

This fishing vessel replaces the owner’s previous vessel of the same name, which was also built by the yard in 2010, and is intended to fish out of Fraserburgh in the North East of Scotland, targeting primarily prawns in the North Sea region.

EXCEL is a new design of fishing vessel, designed between the yard and local Naval Architecture & Consultancy firm Macduff Ship Design. At the owner’s request, the vessel has an overall length of just below twenty metres. However, as there was no requirement for the registered length to be below the ‘under-ticket’ size, the bow was free to be optimised for maximum efficiency and is of similar design to that featured in some of the yards larger designs, such as the VENTURE IV or ZENITH.

The design of the EXCEL began in early 2021 with the contract signed in the spring. Derek and son Phil were keen to build a new modern trawler, a little larger than their previous vessel to offer improved comfort for the crew along with a bit more speed for steaming to the grounds and better fuel efficiency whilst towing. At the same time, the owners were very keen to stick to a similar internal layout as their existing vessel as its working arrangement had been well proven over the years. It was also felt that this would help make the transition for skipper and crew to the new build smooth.

As has become customary in recent years, the yard worked closely with the Wolfson Unit in Southampton who conducted a Computational Fluid Dynamics analysis of the existing hull along side a couple of variants of new concept models. This helped the yard to refine the design and ensure that a step forward was being taken with regard to reducing hull resistance / improving energy efficiency.

With the initial design complete the construction plans were drawn up by Macduff Ship Design and submitted to MCA for plan approval. The hull of EXCEL is built entirely from steel, apart from the wheelhouse and mast which are aluminium, and features a double chine hull form, transom stern and modern bow designed to cut cleanly through the sea with less energy leading to a reduction in fuel consumption and emissions along with increased crew comfort. In broad terms the layout of the EXCEL is similar to some of the other recent new builds produced by the yard. Below deck features the cabins, engine room, fish hold and a large freshwater tank forward of the collision bulkhead. Whereas above deck is situated the aft shelter, galley/mess and side passage area, fish processing area and then forepeak where the trawl winch is situated.

A bespoke hydraulic deck machinery package was fabricated by the yard comprising of a triple barrel winch featuring a Hagglunds compact CA140 motor, two split net drums complete with two Hagglunds compact CA70 motor per drum and a cod end lifting winch. Thistle Marine of Peterhead supplied both the MFB8 landing crane and MBK7 power block crane, both of which featuring a slew ring base. Primary hydraulic power is provided by two pumps driven from the gearbox PTOS, whilst secondary hydraulic power is provided by a small electro-hydraulic system featuring a 45 kW electric motor coupled to a hydraulic pump which can retrieve the fishing gear in an emergency.

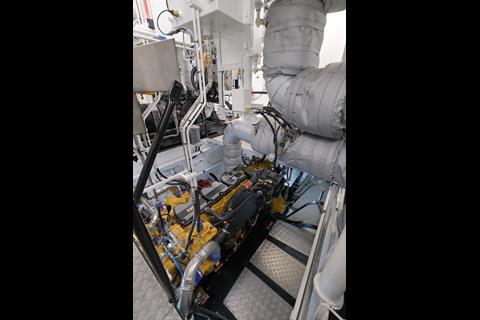

The EXCEL sees the yard return to work with Novga (previously Heimdal) who supplied the yard with many CPP stern gear packages throughout the 80’s and 90’s. The propulsion package features a 2.2 m controllable pitch propeller, housed within a nozzle, coupled to a large reduction gearbox complete with two PTOs for hydraulic power, driven by a Caterpillar C18 main engine.

The C18 main engine on EXCEL is the first IMO Tier III engine to be fitted by the yard. A SCR and urea/AdBlue system is fitted, provided by Xeamos of the Netherlands, which allows the engine to meet the new, more stringent emission standards set by the IMO, resulting in the cleanest emitting new build delivered by the yard to date. Certification of the engine and SCR system was arranged by Finning CAT who assembled the complete system on their test bed in Cannock, with witnessing and certification provided by DNV/GL. The system was demonstrated to work well during sea trials where the 35 dB reduction SCR silencer helped the reduce noise levels throughout the vessel.

Cooling systems for all engines and hydraulics onboard are served by box coolers supplied by Blokland Non-Ferro.

Electrical power onboard is provided by two Mitsubishi generator sets supplied by Macduff Diesels Limited, each with a rating of 98 kWe and of sufficient size to run the vessels power independently providing complete redundancy.

The electrical systems onboard were designed and fitted by R.D. Downie who also fabricated the vessels switchboard and control panels for all the pumps and motor starters. In addition to this R.D. Downie also provided the fire, bilge and gas alarm systems onboard along with the navigation light panel and assisted with the installation of the navigation equipment.

The fish processing deck features a catch handling system built by the yard and Northeast Fabricators. A separate compartment is formed within the fish processing area which house both the ice plant room as well as an access hatch and fixed permanent stair to the hold. The fish hold refrigeration system along with ice machine was supplied and fitted by Premier Refrigeration.

The vessel was fully painted by the yard with Jotun products applied to a comprehensive marine spec.

The high specification navigation package was supplied and fitted onboard by Woodsons of Aberdeen, please contact Steven Wood for full details.

A Notus net monitoring package is fitted provided by Seafield Navigation of Fraserburgh.

| GENERAL PARTICULARS | |

|---|---|

| Length overall | 19.99 m |

| Length Registered | 19.17 m |

| Beam | 7.40 m~ |

| Depth | 4.21 m |

| Depart port displacement | 260 t |

| Fresh water capacity | 11000 li |

| Oil fuel capacity | 16000 li |

| Hold capacity | 600 boxes |

| Speed | 10.0 knots |

| Crew | 6-8 |

LIST OF MAJOR SUPPLIERS

Caterpillar C18 main engine supplied by Finning Power Systems, UK Nozzle supplied by Kort Propulsion, UK

Propeller and Gearbox supplied by Novga, Norway

Construction drawings and stability information supplied by Macduff Ship Design Generator sets supplied by Macduff Diesels Ltd, UK

Box cooling systems for each engine and the hydraulic circuit supplied by Blokland Non Ferro, Netherlands

Pumps supplied by Azcue Pumps SA, Spain

Deck machinery equipment supplied by the yard Deck cranes supplied by Thistle Marine, UK

Fire doors supplied by B-15 Marine Ltd, UK Weathertight doors supplied by Winel, Netherlands Rudder system supplied by the yard

Steering gear supplied by Scan Steering APS, Denmark

Wheelhouse windows and portlights supplied by HK Van Wingerden & An BV, Netherlands

Fish handling system supplied by the North East Fabricators, UK Refrigeration system and ice machine supplied by Premier Refrigeration, UK Paint system by Jotun, UK

Wheelhouse chairs supplied by Norsap, UK

Oil fuel filter/separator and main engine oil fine filter supplied by CC Jensen, UK Pressure washers supplied by Grampian Power Clean, UK

Anchors and chain supplied by Fendercare Marine, UK

Switchboard and electrical system supplied and installed by R D Downie Limited, UK

For details of the fishing gear & electronic equipment package contact the owner

For more information contact:

Macduff Ship Design

+44 (0)1261 833 825 | info@macduffshipdesign.com