Fish farming, or aquaculture, and specifically salmon aquaculture, is the fastest growing food production system in the world. In the late 1960s, faced with declining wild stocks, Norwegian fishers began “farming” Atlantic Salmon in open pens on the coastline.

The Crosby Group, through its Gunnebo Industries brand, has been a part of the industry since the beginning. Through technological development and increased market demand, the industry has grown exponentially. The Crosby Group has continually evolved its products to facilitate the installation, use, and inspection demands of the fast-moving aquaculture sector, contributing to higher safety in an environment where people and equipment are facing increasing challenges.

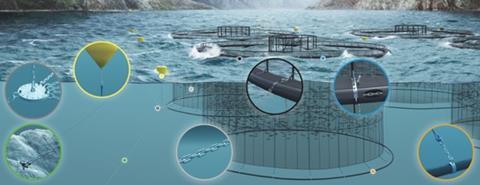

The products manufactured by The Crosby Group are commonly used in harsh environments and often in operations involving high risk to people and property. Whether that’s lifting on an offshore oil rig, lashing a heavy piece of equipment on a trailer, or mooring in the marine industry. The products it manufactures for the aquaculture industry are hidden under the water but the functions they perform, securing the fish pens to each other and to the bottom of the sea, are essential.

There have been several instances where the moorings have broken, and the impact of a mooring failure can be severe. One incident on a salmon farm in North America released 250,000 non-native Atlantic salmon in the Pacific Ocean and caused an estimated loss of revenue of over $10,000,000 for the company, as well as a significant fine. Another mooring incident in Chile led to a fatal accident in 2020. All such incidents are avoidable with the right, high-quality product from a reputable manufacturer, designed specifically for the application.

Rob Van Put, director global aquaculture and fishing at The Crosby Group, says, “All of our aquaculture products are third-party approved and meet or exceed relevant Norwegian aquaculture standards, which are the leading standards globally.” He adds, “In all instances, we not only deliver the best, vertically integrated manufacturing processes to the industry, but we design product that adds immediate safety and efficiency to the point of use, whether it be for installation, durability, inspection, or maintenance purposes. Our aquaculture range of products is engineered and tested to work together, ensuring fitment and performance.”

The key factor when designing a mooring system is safety, and The Crosby Group’s portfolio is designed and manufactured with the rigors of this challenging industry in mind. Resistance to shock, fatigue, and corrosion are hallmarks of the equipment and needed when many farms are placed in inaccessible, remote locations which often see high winds and waves. Typically, the faster the water, the more oxygen is present, and the healthier the fish, which means these farms are being located further offshore than ever before. The demands placed on the underwater rigging and mooring equipment are therefore even greater.

Such farms are based on floating high-density polyethylene (HDPE) cage systems, which are usually part of a farm grid where cages are moored together. A mooring bolt (or anchor; depending on seabed characteristics) secures the mooring line to the seabed. A series of shackles and chains connect to ropes and a connection plate, above, where more shackles and chain connect to the buoy and cages.

Van Put says, “The nature of fish farming means the industry is more about what is invisible beneath the surface of the water than what is above. We are specialized in high energy, remote sites. Sailing there takes a lot more time, so replacing items is more expensive and time consuming. The trend is for the aquaculture sector to seek higher energy, cleaner water to better oxygenate stock, meaning that ancillary equipment needs to be more reliable and durable. Thousands of shackles and other fittings as well as hundreds of kilometers of chain are installed each year.”

The Crosby Group works closely with all the major manufacturers of aquaculture pens to understand the challenges they’re facing and how it can improve its products to help aquaculture sites be safer and more efficient. One example is the new swivel mooring bolts.

Mooring swivel bolt

Mooring bolts have been on the market a long time and are commonly used with rock seabed. However, based on the feedback from the operators and installers, two issues were uncovered. One, when you have high energy sites that move the pens, a fixed bolt creates unnecessary stress to the system; and two, there’s risk of the chain getting tangled with the bolt as the cages move. The new Gunnebo Industries branded mooring swivel bolt allows the mooring bolt to have free rotation after the product is installed. This unique feature allows the connection to rotate as the force is applied, reducing stress, and removing the possibility of chain entanglement problems during and after install.

The swivel is designed to rotate horizontally and the shackle to move vertically. There are grooves in the lower part of the bolt, to ensure optimal fastening. The bolt is combined with the swivel and a support plate that are all hot dip galvanized. The mooring swivel bolt is suitable for installation by remotely operated underwater vehicle (ROV). Another significant benefit is that the design also allows the mooring line to have more than one connection attached to a single mooring bolt.

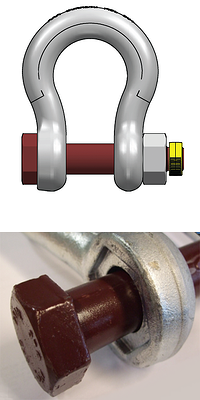

Connecting shackle

Another example is the recently launched Gunnebo Industries branded Connecting Shackle No. 851, with its unique feature of a counter sunk bolt, which locks the shackle. The shackle also offers increased material thickness in the bow which improves the fatigue resistance. Its main purpose is to connect the connection plate (lifting lug) to the buoy with chain.

Prior to this new design, aquaculture sites used either a lifting or a mooring shackle but the new 851 design, reimagined through discussions with end users, combines the best of both. While the shackle’s main purpose is to connect the buoy chain to the liftingllug of a connection plate, it has proven to be a multipurpose product that connects various components in aquaculture. This sunken hexagon bolt head will greatly reduce the risk of the bolt unscrewing during use, as well as making the fitting easier for the user. Other features include customized securing options, plastic covered seizing and steel wire, and a stainless-steel cotter.

The industry standard

Van Put continues, “The Crosby Group has been involved in the industry since its inception. We’ve evolved with the industry and continue to help drive it forward with new technology and improvements. However, it’s not only the obvious product features that we’ve worked to perfect throughout the years, but also the details, such as adding more material to the shackle bow to increase the product life span and fatigue resistance. Continuous improvement to our galvanization process, meanwhile, has reached a point where we today stand out from competition for our excellent, smooth coating, and long corrosion resistance.

“Another example is the range of different securing options for the shackle pin, such as the plastic clips that remove the risk of the pin getting caught on or ripping the net or ropes. Also taking the operator into consideration, one of the reasons why the shackle bolts are countersunk is to allow assembly using only one hand, as you often need to hold the shackle, or yourself, in place when installing shackles in the water. The aquaculture cage manufacturers and the operators trust and choose our products as they’ve been proven in the field for decades; we provide a full system of products and not just individual components and we’re leading the industry in innovation. We’ve become the industry standard when it comes to mooring hardware.”

Finally, let’s share some practical tips on what to look for in your mooring hardware supplier:

Design

- Are the products designed for the specific application or general purpose?

Quality program

- Are the supplier’s critical production processes in-house?

- Does the supplier provide in-house design and construction?

- Does the supplier offer full traceability?

- Is 100% testing performed?

- Are the products approved according to relevant certificates?

Liability

- What coverage does the manufacturer have?

- What is the country of origin? Is liability enforceable in the country of origin?

- Warranty? Does the manufacturer have warranty against production defects?